ASME/SFA 5.4, SFA 5.9, and SFA 5.22 P No. Welding is good practice for all stainless steels. Dirt, oils, and paint can cause weld defects.

ASME Boiler and pressure vessel code (BPVC) has assigned certain numbers to base metals as well as to filler metals (electrodes).

For base metals, ASME has assigned two number system, these are;

- P Numbers

- Group Numbers

- American Welding Society online bookstore. Here you can purchase all AWS publications PDF and Hardcopy format.

- With Warm Regards, Prakash Verma Metallurgist-Drilling Riser Systems QS Supply Chain. Aker Solutions Supply chain hub-India AkerSolutions Tel.+91-20-,6.

For filler metals, the number system which is assigned, are as follows;

- F Number

- A Number

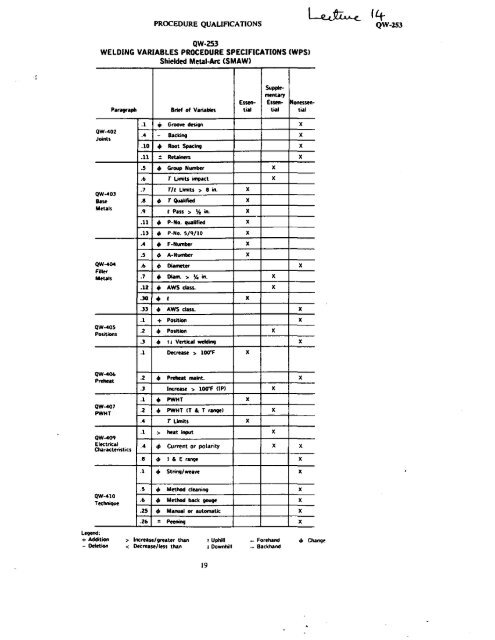

These numbers can be found in ASME BPVC Section IX, please see Table–1 for details;

Table – 1

BASE METAL GROUPING:

The main purpose of assigning this number system is to reduce the number of procedure qualification records (PQR). Conducting a procedure qualification requires a lot of time and money due to the following procedural requirements;

- Preparation of test coupon

- welding of test coupon and

- sending it to a lab for destructive test

Hence, to reduce these costly and time-consuming activities, ASME has done grouping of base metals and has assigned certain P numbers to each group of metals. This grouping of base metals has been done on the basis of the following parameters;

- Material composition

- Weldability

- Mechanical property

Though all materials of the same ‘P’ number doesn’t exhibit the same properties, but after considering the above-mentioned parameters, ASME has done this logical grouping.

Why this grouping is required?

Suppose, if we change the base metal from an existing qualified WPS and if the new base metal falls in the same ‘P’ number then the requalification of the existing WPS is not required, it means no need for a new PQR.

But this doesn’t mean that one can easily substitute the base material, from existing WPS, of same ‘P’ number at any time. Whenever there is a change in the base material from existing WPS, the compatibility shall be considered with regards to the following factors;

- Metallurgical property

- Mechanical property

- Design considerations

- Service requirements

- Heat treatment

Table–2 shows the assignment groups for various metals and their alloys (according to ASME BPVC).

Table – 2

What Is Sfas Army

Now that we have understood ‘P’ numbers let’s move on to group numbers. Group numbers are subsets of ‘P’ numbers assigned to ferrous based metals. Group numbers are assigned only to those materials which require toughness testing for the qualification of its WPS.

We will take an example of SA516 Gr 65 from table QW/QB-422 (Page – 118 of ASME Section IX, 2017 edition), we can find out the following values;

Base material – SA516 Gr 65

- Tensile strength (min.) – 65 Ksi (or 450 Mpa)

- P-No. – 1

- Group number – 1

- Nominal composition – C-Mn-Si

- Typical product form – Plate

Another grouping of base metals was the ‘S’ numbers, but the ‘S’ number is not used nowadays. It was deleted from ASME in 2009.

S Numbers were assigned to those materials which were acceptable for use by the ASME B31 Code for Pressure Piping, or by selected Boiler and Pressure Vessel Code Cases, but were not included in section II of ASME Boiler and Pressure Vessel (BPVC). Base metals that were previously assigned ‘S’ Numbers were reassigned the corresponding P Numbers or P Numbers and Group Numbers.

FILLER METAL (ELECTRODE/WELDING ROD) GROUPING:

The F Number: F number grouping (for filler metals) is done to reduce the number of welding procedure specifications (WPS) and welder performance qualifications. The basis for F number grouping is usability characteristics. The usability characteristics fundamentally determine the ability of a welder to produce sound welds with a given filler metal. Hence it is assumed if a welder can make satisfactory weld with a particular filler metal, he will be able to weld with all the filler metals belonging to that particular ‘F’ number.

Table-3 shows a brief summary of ‘F’ and filler metals (according to ASME BPVC, Table: QW-432).

Table – 3

The ‘F’ number grouping doesn’t imply that one can easily substitute the filler metal (electrode/welding rod), from existing WPS, of the same ‘F’ number at any time. Whenever there is a change in the filler metal (electrode/welding rod) from existing WPS, the compatibility shall be considered with regards to the following factors;

- Metallurgical property

- Mechanical property

- Design considerations

- Service requirements

- Heat treatment

The A Number: Another type of grouping for filler metal or welding rod is the ‘A’ Number. ‘A’ number grouping has been done on the basis of the chemical composition of the deposited weld metal. This can be found in ASME BPVC Section IX, Table – QW-442).

Please watch the video (given below) for more clarity on this topic;

Also read: Thickness range for welder qualification

Also read: Welding Symbols

Also read: How to write a welding procedure specification

Also read: CSWIP Question Answers

Also read: Welding Electrodes/Filler metal

(adsbygoogle = window.adsbygoogle || []).push({

google_ad_client: “ca-pub-7169364926257281”,

enable_page_level_ads: true

});

ASME P Number

To reduce the number of welding and brazing procedure qualifications required base metals have been assigned P-Numbers by the ASME BPVC. Ferrous metals which have specified impact test requirements have been assigned Group Numbers within P-Numbers.

These assignments have been based on comparable base metal characteristics, such as:

Sfa Number In Welding

- Composition

- Weldability

- Brazeability

- Mechanical Properties

Indiscriminant substitution of materials in a set of P-Numbers or Group Numbers may lead to problems or potentially failures. Engineering assessment is necessary prior to a change in materials.

When a base metal with a UNS number Designation is assigned a P-Number, then a base metal listed in a different ASME material specification with the same UNS number shall be considered that P-Number.

The table below is a guide and is for instructive purposes only. Anyone specifying materials or requirements should refer directly to the ASME Boiler and Pressure Vessel Code to specify materials.

| P-Numbers | Base Metal (Typical or Example) |

| 1 | Carbon Manganese Steels (four Group Numbers) |

| 2 | Not Used |

| 3 | Half Molybdenum or half Chromium, half Molybdenum (three Group Numbers) |

| 4 | One and a quarter Chromium, half Molybdenum (two Group Numbers) |

| 5A | Two and a quarter Chromium, one Molybdenum |

| 5B | Five Chromium, half Molybdenum or nine Chromium, one Molybdenum (two Group Numbers) |

| 5C | Chromium, Molybdenum, Vanadium (five Group Numbers) |

| 6 | Martensitic Stainless Steels (Grade 410, 415, 429) (six Group Numbers) |

| 7 | Ferritic Stainless Steels (Grade 409, 430) |

| 8 | Austenitic Stainless Steels · Group 1 – Grades 304, 316, 317, 347 · Group 2 – Grades 309, 310 · Group 3 – High Manganese Grades · Group 4 – High Molybdenum Grades |

| 9A, B, C | Two to four Nickel Steels |

| 10A, B, C, F | Various low alloy steels |

| 10H | Duplex and Super Duplex Stainless Steel (Grades 31803, 32750) |

| 10I | High Chromium Stainless Steel |

| 10J | High Chromium, Molybdenum Stainless Steel |

| 10K | High Chromium, Molybdenum, Nickel Stainless Steel |

| 11A | Various high strength low alloy steels (six Group Numbers) |

| 11B | Various high strength low alloy steels (ten Group Numbers) |

| 12 to 20 | Not Used |

| 21 | High Aluminum content (1000 and 3000 series) |

| 22 | Aluminum (5000 series – 5052, 5454) |

| 23 | Aluminum (6000 series – 6061, 6063) |

| 24 | Not Used |

| 25 | Aluminum (5000 series – 5083, 5086, 5456) |

| 26 to 30 | Not used |

| 31 | High Copper content |

| 32 | Brass |

| 33 | Copper Silicone |

| 34 | Copper Nickel |

| 35 | Copper Aluminum |

| 36 to 40 | Not Used |

| 41 | High Nickel content |

| 42 | Nickel, Copper – (Monel 500) |

| 43 | Nickel, Chromium, Iron – (Inconel) |

| 44 | Nickel, Molybdenum – (Hastelloy B2, C22, C276, X) |

| 45 | Nickel, Chromium |

| 46 | Nickel, Chromium, Silicone |

| 47 | Nickel, Chromium, Tungsten |

| 47 to 50 | Not Used |

| 51, 52, 53 | Titanium Alloys |

| 61, 62 | Zirconium Alloys |

ASME F Number

The F-number grouping of electrode and welding rod in QW-432 is based essentially on their usability characteristics, which fundamentally determine the ability of welders to make satisfactory welds with a given filler metal. This grouping is made to reduce the number of welding procedure and performance qualifications, where this can logically be done. The grouping does not imply that base metals or filler metals within a group may be indiscriminately substituted for a metal which was used in the qualification test without consideration of the compatibility of the base and filler metal from the standpoint of metallurgical properties, PWHT design and service requirements, and mechanical properties.

| F Number | General Description |

| 1 | Heavy rutile coated iron powder electrodes :- A5.1 : E7024 |

| 2 | Most Rutile consumables such as :- A5.1 : E6013 |

| 3 | Cellulosic electrodes such as :- A5.1 : E6011 |

| 4 | Basic coated electrodes such as : A5.1 : E7016 and E7018 |

| 5 | High alloy austenitic stainless steel and duplex :- A5.4 : E316L-16 |

| 6 | Any steel solid or cored wire (with flux or metal) |

| 2X | Aluminium and its alloys |

| 3X | Copper and its alloys |

| 4X | Nickel alloys |

| 5X | Titanium |

| 6X | Zirconium |

| 7X | Hard Facing Overlay |

Note:- X represents any number 0 to 9

Reference: iiwindia literature and ASME Section IX

Keep reading, happy welding

Thank you,

KP Bhatt